YZE Home / Competence Centers / Intelligent Production Systems

YZE

Intelligent Production Systems

Intelligent Production Systems Working Areas

- Increasing the machine-human interaction within the scope of Industry 4.0, especially with smart technologies using artificial intelligence applications.

- Effective use of smart production technologies together with digital transformation for the development of applications that work in production and production-related ecosystem and create value for customers and stakeholders.

- Increasing production efficiency and creating process-effective solutions with artificial intelligence-based smart solutions in the fields of management of production processes, cost-effective production, optimum production planning, integration of supply chain management with production planning, increasing customer satisfaction.

- Creation and use of joint development sites such as the model factory.

- Durable Production

- Automotive, Machinery, Engine

- Refineries

- Defense

- Chemistry, Pharmaceuticals, Medical Devices

- Food, Food Production, Packaging

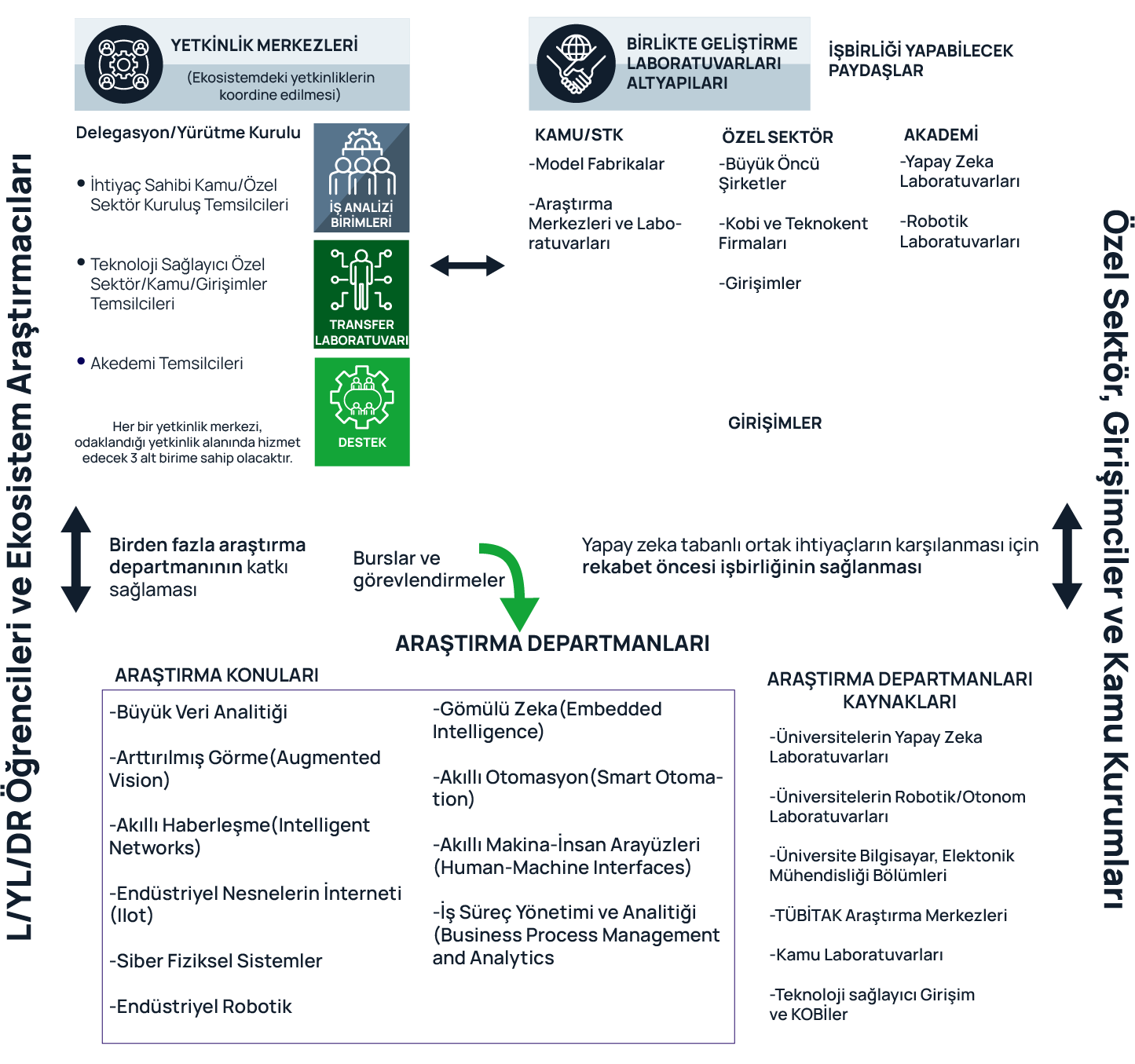

COMPETENCY CENTERS

Intelligent Production Systems Application Areas

- Predictive maintenance applications such as product quality estimation and defective part/product detection using methods such as computer image processing.

- Determination of output quality as a result of continuous monitoring with sensors, optimization of factors affecting output quality, prediction of security problems and similar applications.

optimization of the factors affecting the quality of

predicting etc. applications. - The use of blockchain in the supply chain, automated payments or the use of blockchain for information security in the Internet of Things (IoT) environment at the production site.

- Real-time situation analysis of production with artificial intelligence sensors in the industrial Internet of Things (IoT) used in production, application of methods that reduce energy consumption.

- Demand estimation by modeling customer purchasing behavior and thus ensuring warehouse management with minimum cost.

- Implementation of routine and repetitive work in the production area with robot automation (RPA).

- Making production planning and maintenance estimation by creating a digital twin of the production site.

- Educating a new task to autonomous robots by human interaction using reinforcement learning techniques.

- Developing artificial intelligence-based applications that add value in all processes from raw material supply to customer satisfaction in the production process.

YZE

Intelligent Production Systems Competence Center