BİLGEM

Bioelectronics

National Marker Controller

- General Features

- Activities Performed

- Continuous Activities

With the device developed in the Bioelectronic Systems Department of BİLGEM UEKAE, it is aimed to develop devices that detect tax-paid fuels, to identify chemical marker imitations added to fuels, and to continuously operate the national marker tracking system. With the device, it is aimed to prevent the distribution of fuel obtained through unregistered production and smuggling in the oil market and to increase tax revenues by ensuring maximum control of the fuel market. The device has fully met these expectations and targets throughout the country, thanks to the device, fuel smuggling in the country has been significantly reduced and significant contributions have been made to the national economy with this fuel, which has been included in the tax system.

- New generation marker devices mechanical, electronic and software development studies

- Production and calibration of Marker XP+ instruments

- Replacing XP devices in the field with XP+

- Installation of the central server system

- Interactive application development studies

- Routine device calibrations and maintenance-repair activities

- Auditor trainings

- Updates to device and central software

- Monitoring of the central server system, maintenance-repair activities

- Putting Tamper Switches on Devices

- Interactive application development studies

- R&D activities on the algorithm

Bioaerosol Detection System

- Product information

- Purposes

With the Bioaerosol Detection System Project, which was started in the Department of Bioelectronic Systems, it is aimed to detect aerosols with a diameter of 0.5-10 microns in the air by means of an optical-based system. Devices to be designed according to customer needs; It is aimed not only to be limited to desktop use, but also to be integrated into various manned and unmanned land, air and sea vehicles (armored vehicles, drones, balloons, ships, etc.) to serve our country in civil and military fields. The device to be developed will go into alarm when the size and amount of the threat particles in the air exceed a certain threshold value and the information whether the detected particles are biological or not will be transferred to the software. In the case of biological, threatening particles (bioaerosols) will be collected in a filter and stored for laboratory tests.

Thanks to these studies, which are being carried out for the first time in the field of CBRN in Turkey; in response to the ever-changing threats of chemical and biological warfare agents developed in the laboratory, detection systems in this field will also be nationalized in our country. In this way, an important security vulnerability that may occur due to the "not recognizing a threat not found in the library" of such imported devices will be prevented. The work done for the device also creates an infrastructure for the devices that SSB needs in CBRN and other fields.

FORDEX - Next Generation Document Inspection System

- Product information

- General Features

- Technicial Features

The Next-Generation Document Inspection (FORDEX) developed at TÜBİTAK BİLGEM UEKAE Bioelectronic Systems Department is a system composed of hardware and software modules designed to enhance the capabilities of forensic document examiners for legal purposes. The system aims to visually determine various features that verify or refute the authenticity of the examined document using video cameras, lighting sources, optical tools, and software.

The FORDEX device, which uses the measurement method based on physically measurable optical spectroscopy parameters, introduces a brand new non-destructive method in examining the originality of documents and handwritings with its 3D display software based on radiation intensity.

By using the hyper-spectrum technique, FORDEX can display the details of the reflection, transmittance or fluorescence spectrum at any point on the image by acquiring image and spectrum information at the same time. Powerful opto-electronic elements using the hyper-spectrum method are combined with a brand new design in the device, allowing even small differences in microscopic structures to be captured.

FORDEX TECHNICAL SPECIFICATIONS | |

COLOR CAMERA | 15 MPX |

MONO CAMERA | 12 MPX (Preferred) |

Image Spectral Range | 400-1,000 mm |

Optical zoom + Magnifier Lens | 30x – 150x |

Digital Magnification | 1,920x |

Field of View | 245 x 164 mm |

Max Field of View | 300 x 252 mm |

XY Moving Floor Table | Available |

XY Range of Motion | 70x88mm |

Spectrometer | Available |

Raman | Unavailable |

Temperature & Humidity Control | Available |

Moving Spectrometer System | Available |

Moving Lighting System | Available |

Z Axis Range of Motion | 70mm |

Panel Angular Motion Range | 90o-150o |

Transcutaneous Bilirubinmeter

- Product information

- Working Principle

- Features

The Bilirubinmeter is a device that can test jaundice in newborn babies with optical measurement through the skin, has a completely unique software, hardware and optical architecture, is suitable for routine use, works fully automatically, can transfer results to patient records wirelessly, and provides rapid intervention without effort and pain to the baby, and is also the first bilirubin measurement device developed with domestic and national facilities in Turkey.

In the traditional method, measuring jaundice in newborns is done by taking a blood sample from the baby. However, for babies requiring continuous monitoring, frequent blood sampling can be cumbersome and painful. To address this issue, a multidisciplinary team was formed at TÜBİTAK BİLGEM UEKAE Bioelectronic Systems Laboratory to develop a bilirubin (jaundice) measurement device that can perform measurements entirely painlessly using an optical method.

Neonatal jaundice is visible when bilirubin, a yellow pigment, accumulates in the subcutaneous region. The severity of neonatal jaundice is proportional to the concentration of bilirubin. As the concentration of the bilirubin substance increases, the color of the skin becomes more yellowish. Reflection spectroscopy can be used to quantify the degree of yellow color of the skin. In order to design the optical unit of the device, the mathematical and physical model of the baby's skin was created. In line with the model, the optical unit and the mechanical design suitable for the optical unit were made and the production of the device was started.

- Its software, hardware and optical architecture is one hundred percent original.

- It is suitable for routine use.

- It works completely automatically.

- It can transfer results to patient records wirelessly.

- It can test jaundice in newborn babies by optical measurement over the skin.

- Rapid intervention can be done effortlessly and without causing pain to the baby.

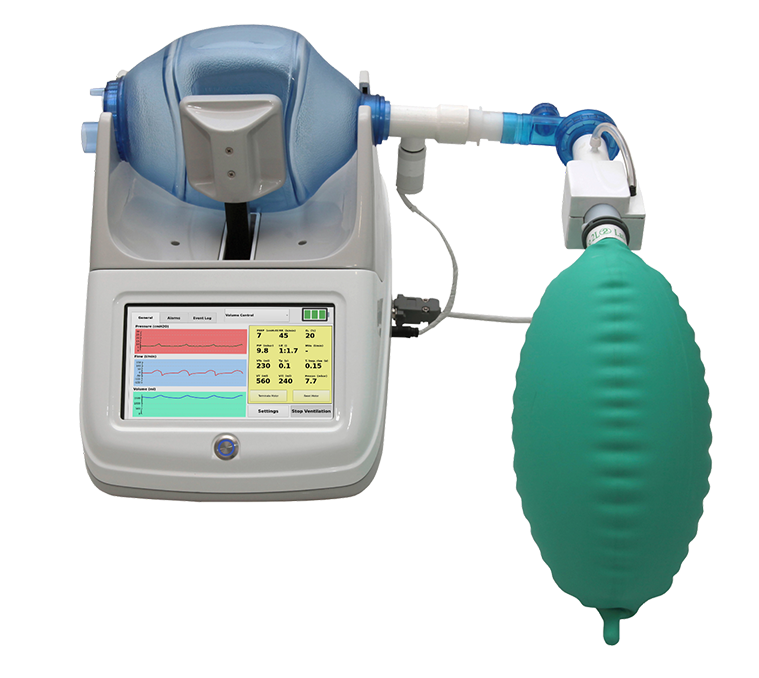

Ambu Bag Based Respirator

- Product information

- General Features

The device was developed at TÜBİTAK BİLGEM UEKAE Bioelectronic Systems Department to ensure healthy and regular breathing of patients in need of respiratory support. Values such as air flow, pressure and oxygen ratio can be controlled with the help of sensors on the device.

In certain situations such as COVID-19, infected patients exhibit severe symptoms, including respiratory distress and shortness of breath. Advanced patients showing these symptoms require treatment in intensive care units at hospitals. During such periods, one of the most crucial devices needed in intensive care units is respiratory ventilators. In the case of an epidemic, the rapid increase in the number of patients also means a rapid increase in the demand for respiratory ventilators. In such emergency situations, the need for respiratory ventilators arises not only within hospitals but also in external environments, including mobile patient transport vehicles, to meet the demand for a larger number of ventilators.

In order to meet this demand, discussions are ongoing with companies capable of conducting mass production, sales, and after-sales support activities within the country for a ventilator device that comes with superior features such as battery, touch screen, and data transfer capabilities. The ventilator is designed to be customizable according to customer needs.

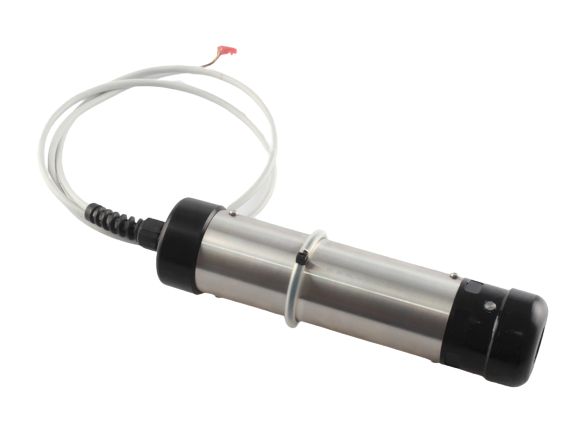

Dissolved Oxygen Sensor

- Product information

- gains

Dissolved oxygen sensors and controllers used in wastewater treatment plants (WWTP) in Turkey are purchased from abroad. It is planned to develop a domestic dissolved oxygen sensor and control unit in order to remove this dependency on abroad. In this context, a prototype was produced by developing a dissolved oxygen probe that measures the dissolved oxygen value in wastewater in cooperation with TÜBİTAK BİLGEM and TÜBİTAK MAM. Within the scope of the project, the optical, mechanical, electronic and algorithm design and production of the device were carried out in the Bioelectronic Systems Department.

The number of WWTPs in Turkey is expected to triple by 2023. Many industries such as chemicals, energy, biopharmaceuticals, biopharmaceuticals, food, beverages and fish farms are other markets. Dissolved oxygen is one of the parameters that must be monitored in facilities with an installed capacity of 5,000 m³/day and above according to the communiqué on WWTPs. In this sense, the market will expand with the increase in population and the commissioning of new facilities.

The dissolved oxygen sensor and control unit will be utilized not only in wastewater treatment plants but also for online monitoring of dissolved oxygen in seafood (fish, shrimp, etc.) production farms, lakes, rivers, and streams.

It is aimed to bring the following benefits to our country with the start of production, marketing and sales activities of dissolved oxygen sensors, all of which are currently imported:

- Having a completely domestic and national production infrastructure of the product,

- Elimination of import dependency, which is increasing gradually and amounting to approximately 20 million USD annually,

- Contributing to the national income of the country thanks to the export potential of the product,

- Contributing to employment by introducing a new investment item to our country,

- Initiating similar studies in different fields thanks to the knowledge (know-how), experience and human resources in the field of sensor technology,

- Encouraging the private sector for limited production based on sensor technologies in our country.

Company Marker Control Devices and Inspection System

- Product information

- General Features

The aim of the project is to enable fuel companies to identify the fuels they sell and improve the quality of their services. In this context, devices and software are being developed in the laboratory using entirely domestic resources to control the company markers specially designed for the gasoline and diesel types distributed by the company. The measurement results obtained from these devices are transferred to a centralized platform, allowing company officials to track and monitor them online.

As part of the project, maintenance, repair, and calibration processes of the Company Marker Measurement Devices produced for a fuel company, as well as the production of new devices upon request, server maintenance, repair, and management, software development, field applications, and R&D studies aimed at improving measurement quality have been carried out.

With the Company Marker Measurement System Project, first of all, in order for the measurement devices produced to operate with high accuracy, all kinds of fuel with different chemical content and matrix structure imported and sold by the company from different countries can always measure the same company marker (marker) value, It is aimed to read the correct value even in seasonal temperature changes and fuel oil additive changes and to ensure that the device operates correctly and properly, to perform device calibrations in 6-month periods, to ensure that the online tracking system is constantly operational, to monitor fuel oil quality with continuous field monitoring, to eliminate possible device malfunctions and to carry out R&D for higher accuracy.

The device was used by OPET company to monitor the fuels used at their stations.

DUHAN BETA Bioerosol Detection System

- Product information

- Purposes

- Technicial Features

The Beta version prototype is designed as a desktop display for the ongoing studies aimed at detecting the presence of bioaerosols in the air, which pose a potential threat to human health.

The device is designed with the following features both on its own screen and through the computer interface to which it is connected:

- Detection of aerosols in the air,

- Deciding whether it is biological or not,

- Extracting the concentration-size distribution,

- Alarm generation,

- Sample collection for further examinations.

In this way, the device has the feature of both giving information about the presence of aerosol in the environment and announcing the presence of an aerosol (bioaerosol) with an alarm, which has a vitality feature that exceeds the determined threshold value.

In recent years, the possibility of developing microorganisms that have been genetically modified to increase their disease-causing effects, make detection difficult and directed microorganisms increases the danger of biological weapons as weapons of mass destruction. In this context, a project was initiated at TÜBİTAK BİLGEM in 2022 to develop a Bioaerosol Detection System.

By the end of 2022, the table-top device, which was brought to the final stage as targeted, was developed as a laboratory prototype. With this device, called DUHAN Beta, the goal of continuously controlling the ambient air and generating an alarm when the amount of aerosol in the air exceeds the specified threshold values has been successfully achieved.

The project aims to detect aerosols with a diameter of 0.5-10 microns with an optical-based system. The particles in the ambient air transferred to the system in the developed device through pumps are measured by laser stimulation. When the size and quantity of the threat particles in the air exceed a certain threshold value, the device is alarmed and it is understood whether the detected particles are biological or not (bioaerosol). If they are biological, the threat particles can be concentrated and stored in the filter. The developed DUHAN Beta version device decides the presence/absence of biological material.

The work carried out in the Project also creates the infrastructure for devices for the CBRN and other needs of the SSB. In line with the needs to be determined, the device can be integrated into manned and unmanned land, air and sea vehicles, as well as customization for different purposes such as on-site detection, sampling, monitoring of important institutions and mass areas, continuous monitoring supported by artificial intelligence, VIP personnel protection, online data transfer.

Beta Version System Features:

- Particle size1: 0.3-5 µm

- Number of channels: 14 (adjustable)

- Maximum concentration: 24,000 cm-3

- Laser wavelength: 405nm

- Detection angle: 90°

- Example flow rate: 0.25-1 LPM (adjustable)

- Guide flow rate: 0.25-5 LPM (adjustable)

- Weight2: 22kg

- Dimensions2: 33 cm (H) × 48 cm (D) × 43 cm (W)

- Strength2: 220 VAC, 50/60 Hz, 90 W

Customizable/Addable Features

- Communication: USB / Ethernet / GSM

- Device control: Display / Graphical interface / Terminal

- Alarm output: Visual / Logic / Audio

- Other: Sample spooling, authorization, registration, GPS

- This is the particle size in the beta version. Wider ranges are available upon request..

- Values in beta version, can improve by 50%..